In the previous

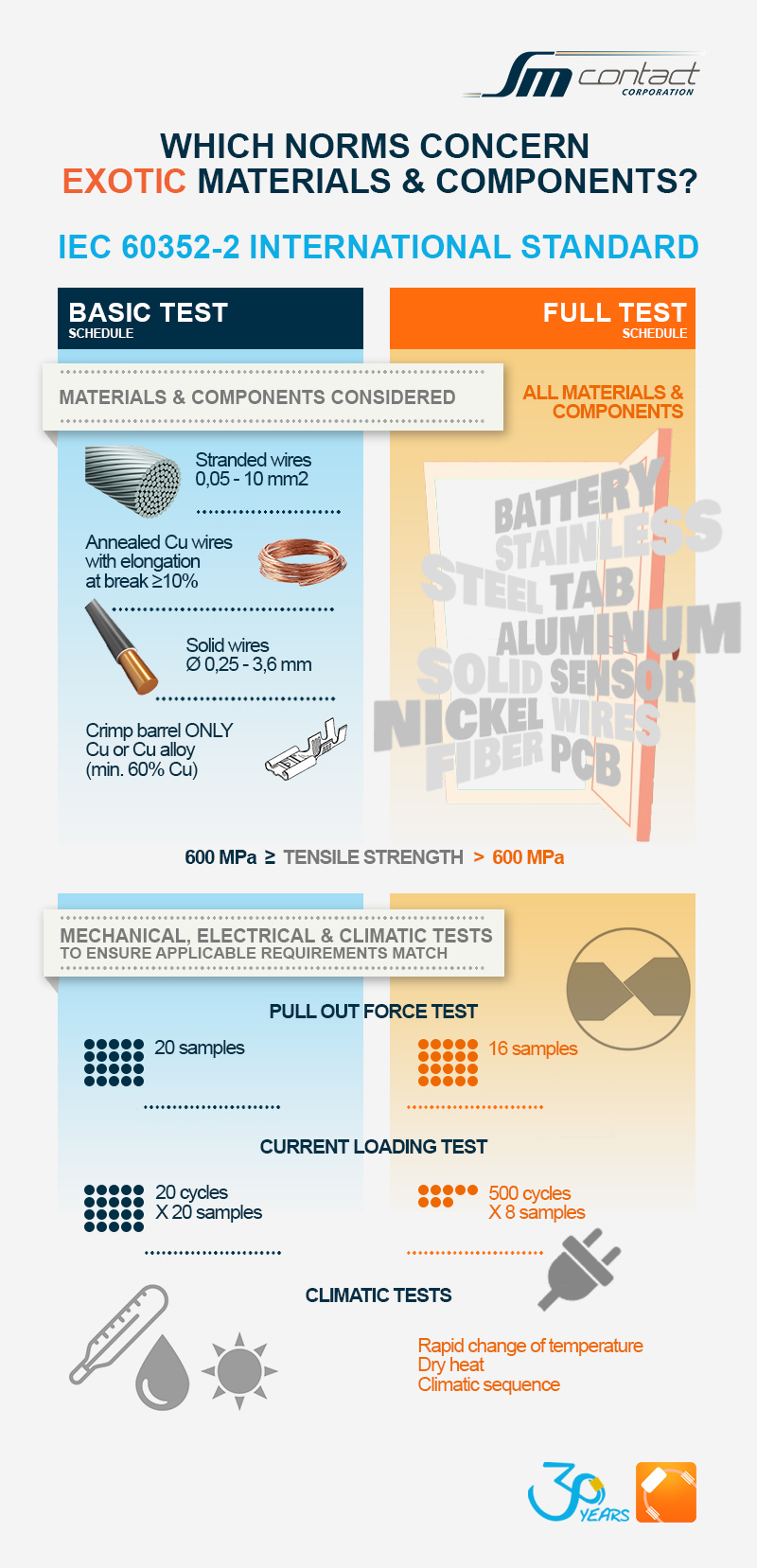

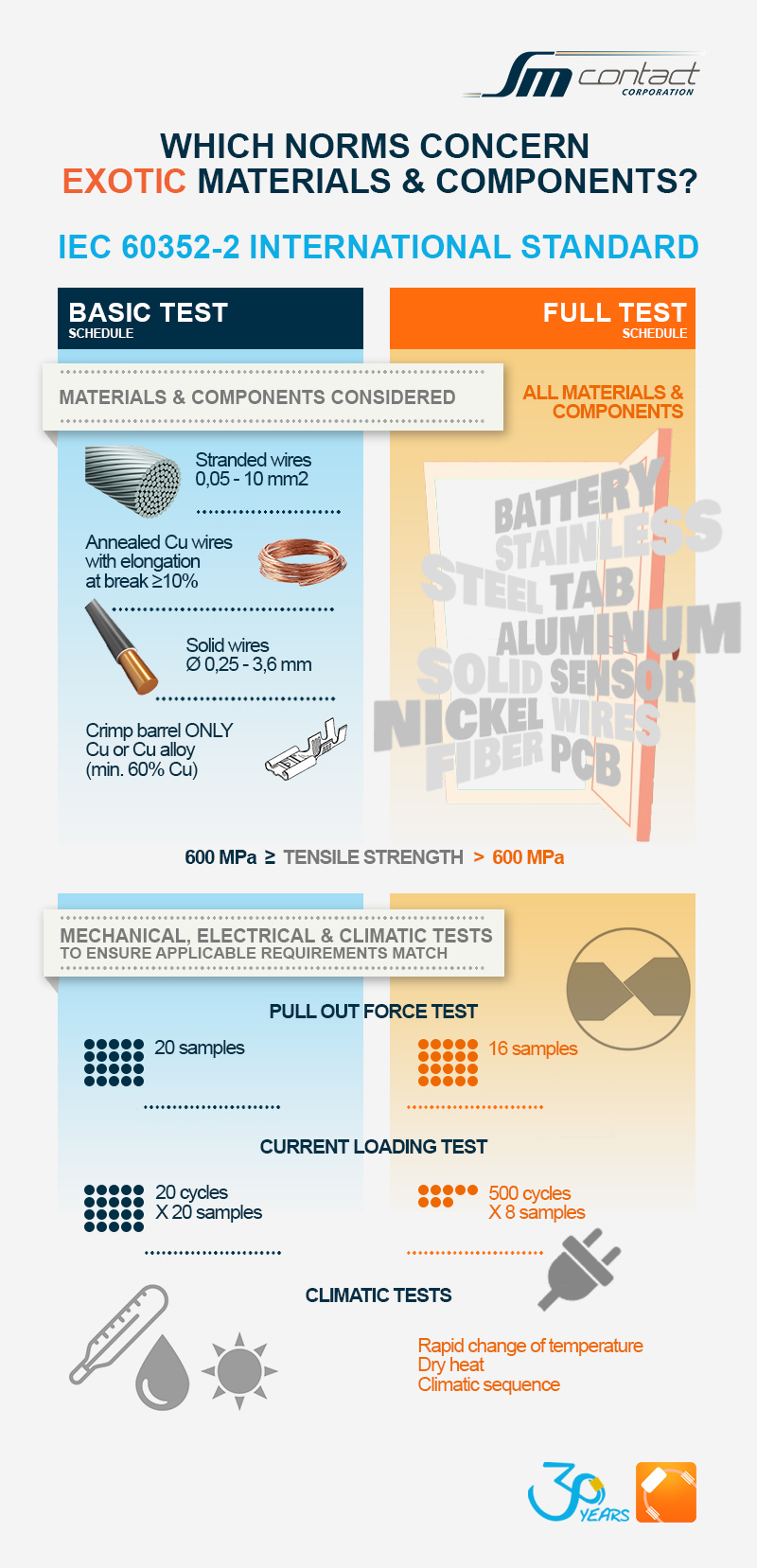

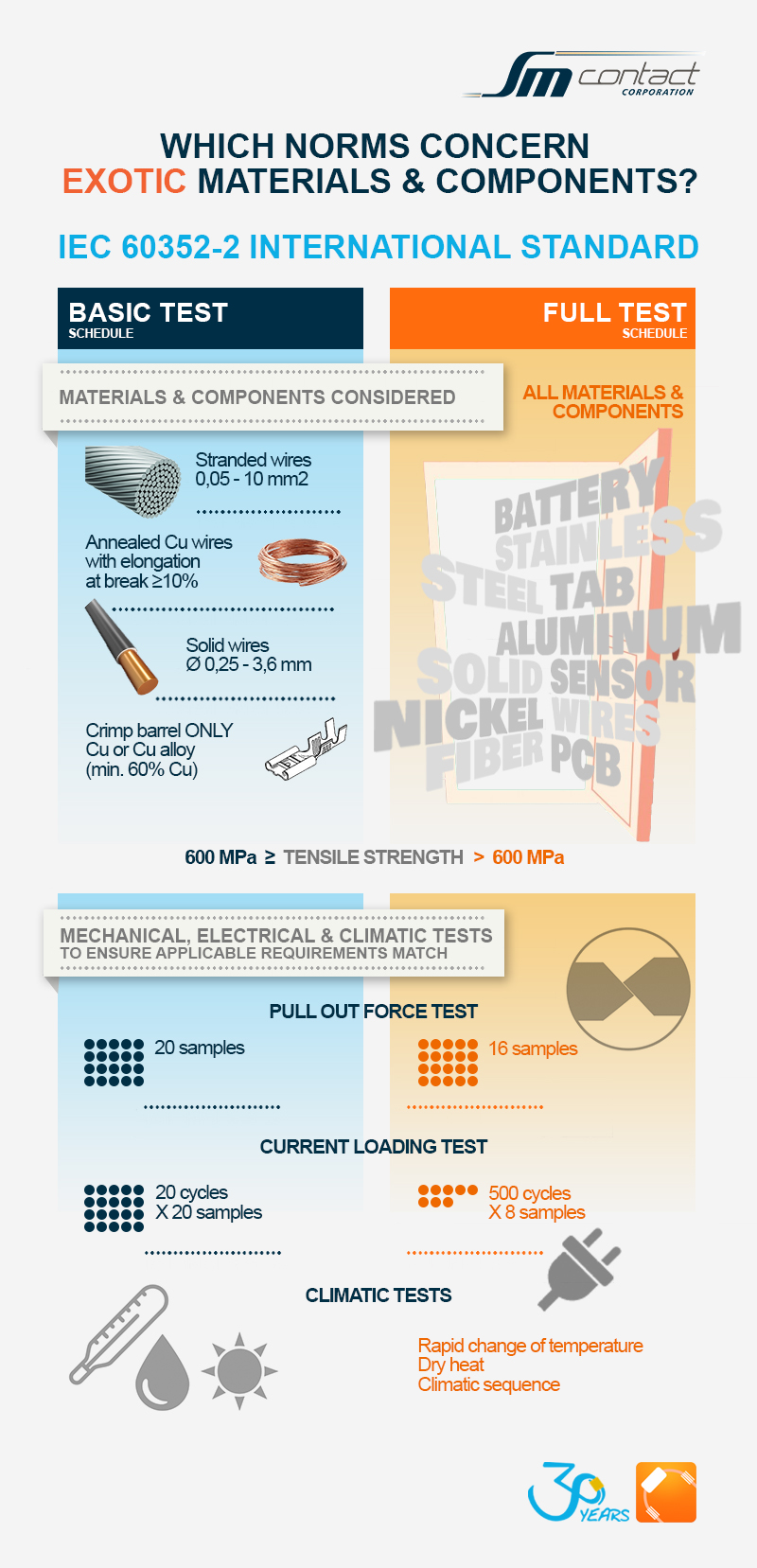

“Useful tips” we investigated widely applied industrial crimp norms and arrived at the conclusion that they do not concern exotic materials (aluminum, steel, fiber, etc.) and components (e.g. battery tab, PCB, sensor). So, how to evaluate your such-like connection? For these cases there is a help of IEC 60352-2 norms giving test schedules and techniques for crimp connections.

According to the Standard, it’s necessary to perform one of the following test algorithms depending on materials and components types:

1. Basic test schedule

Basic test schedule for 0,05-10 mm2 cross section stranded wires, 0,25-3,6 mm diameter solid wires with copper or copper alloy (content min. 60% of copper) terminals; wires made of annealed copper and quite less plastic one, having 10% elongation before break;

2. Full test schedule

Full test schedule covers all components and materials, including exotic ones. Connections made with solid wires, nickel, steel, stainless steel or materials exceeding the tensile strength of 600 MPa may be used.

The Basic test schedule entails just pull out force test on 20 samples and 20 cycles of current loading on another 20 samples while the Full test schedule requires pull out force test on 16 samples, an intensive current loading test (500 cycles!) on 8 samples and climatic tests, including temperature rapid change, dry heat and climatic sequence (dry heat, damp heat, cold) on 16 samples.

Obtained results are to be compared with target values giving in corresponding IEC norms such as pull out force and contact resistance graphs. It’s worth mentioning that the latest comes with coefficient values for different barrel materials.

IEC Standard gives other recommendations on components regarding both cases: total contact surface between components must be maximum (keeping in mind the splice length and configuration aspect); materials and finishes must be as close as practicable in electrogalvanic series of metals; very hard and very soft materials combination is not desirable for comparable deformation in both the conductor and crimp barrel, etc.

It may be concluded that the Full test schedule presented in IEC 60352-2 International Standard opens the gate for various connections whatever the components and materials are. Being equipped with this instrument, we know how to do best connection so that fine results in laboratory pass into reliable connections in the field environment.

For reference, the IEC (International Electrotechnical Commission) is a global organization for standardization in the field of electrical, electronic and related technologies, systems and services founded in 1906. It is one of three sister organizations (next to ISO and ITU) that develop International Standards.

[caption id="attachment_2307" align="aligncenter" width="449"]

Which norms concern exotic materials & components?[/caption]

Previous "Useful tips":

Which norms concern exotic materials & components?[/caption]

Previous "Useful tips":

Which norms concern exotic materials & components?[/caption]

Previous "Useful tips":

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957