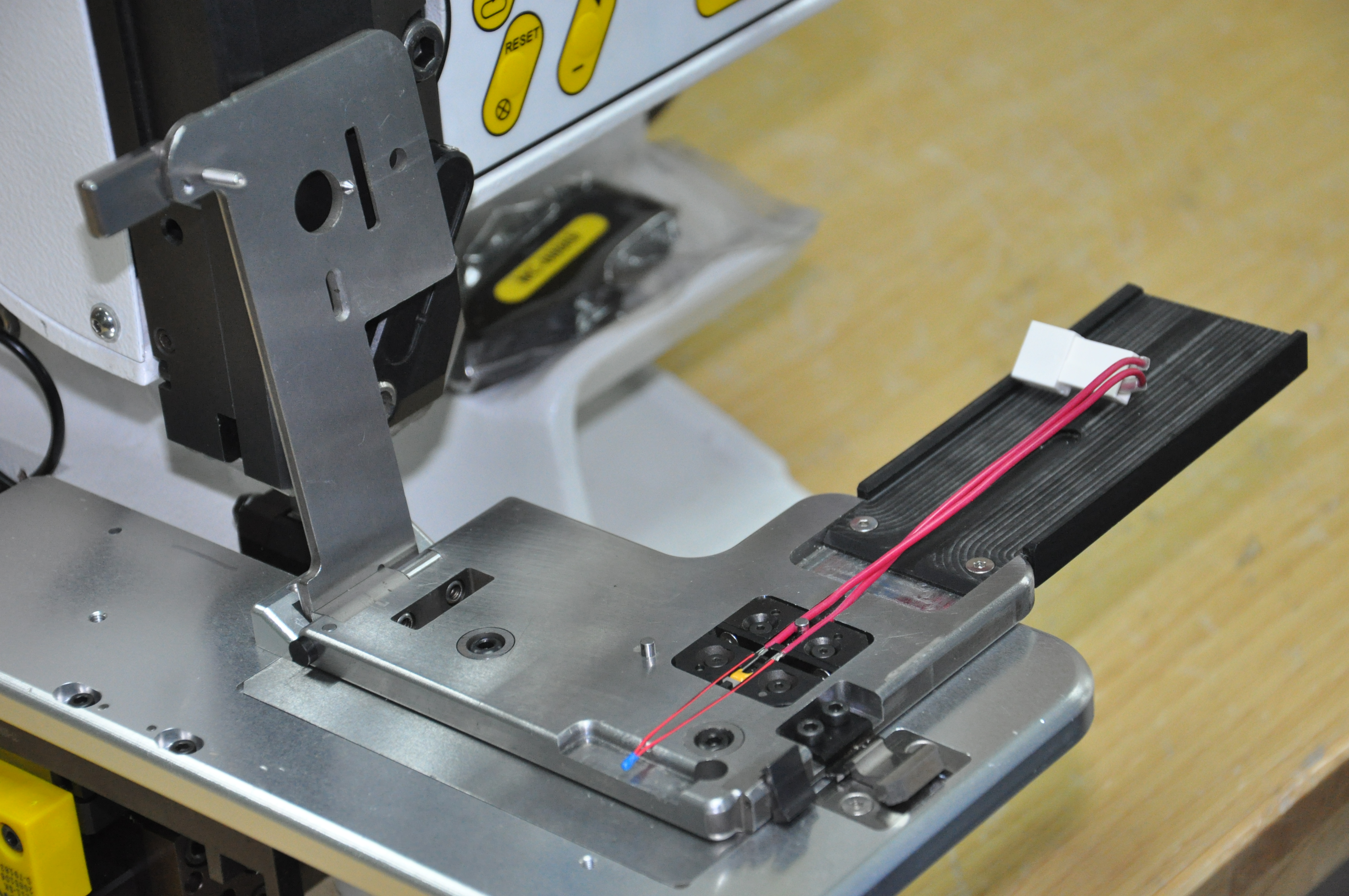

SM Contact has recently finished the project of SM Crimp 2000 with semi-automatic fixture and 6 quick-change jigs. Individual jig for each type of a connection warrants components positioning and precise splice crimping.

New machine was designed to connect 6 different sets of wires, sensors and capacitors. Splice crimping cycle time is 8 sec. Tooling change-over takes less than 5 minutes, while master-operator can manage it even in 3.

Among the other advantage of this SM Crimp version are the following:

1. HMI system – demonstrates the complete work algorithm, eliminating errors;

2. Crimp Force Monitor – calculates force-time curve and detects any deviation from the quality tolerances;

3. Tooling – designed for a tight symmetrical connection;

4. Motorized band feeding system – controls the length of each splice and prevents its damage;

5. Сast iron frame – warrants a perfect stability during crimping.

[embed]https://youtu.be/9nEOEt1XY3I[/embed]

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957