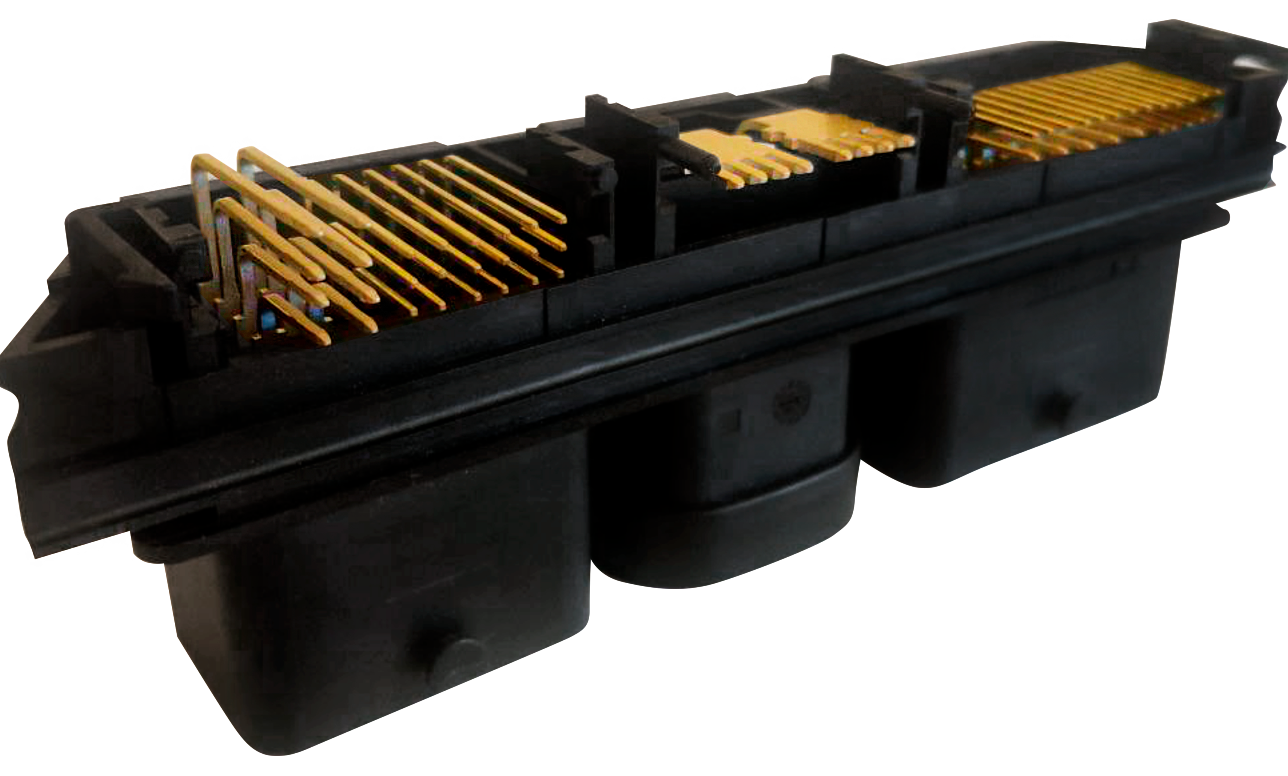

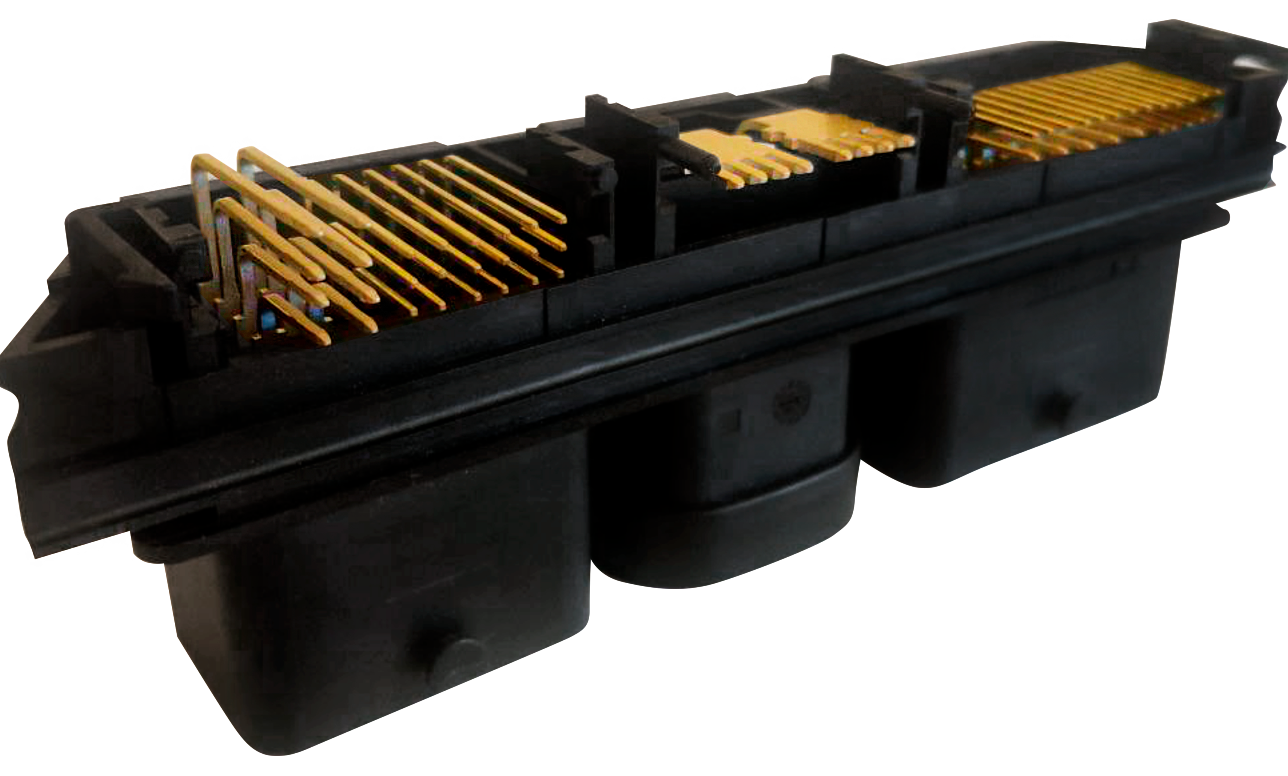

Over the past 10 years, 0.4x0.5 mm press-fit pin has become one of the most in-demand products in SM Contact portfolio. The company supplies around 100 million pins of this type per year. This small eye-of-the-needle (EON) terminal is in wide demand in the automotive industry, especially in lighting electronics, because it’s cost-effective and space-saving. It is designed to replace soldered parts on printed circuit boards (PCB) and connectors.

Advantages of 0.4x0.5 mm press-fit pins:

Advantages of 0.4x0.5 mm press-fit pins:

-

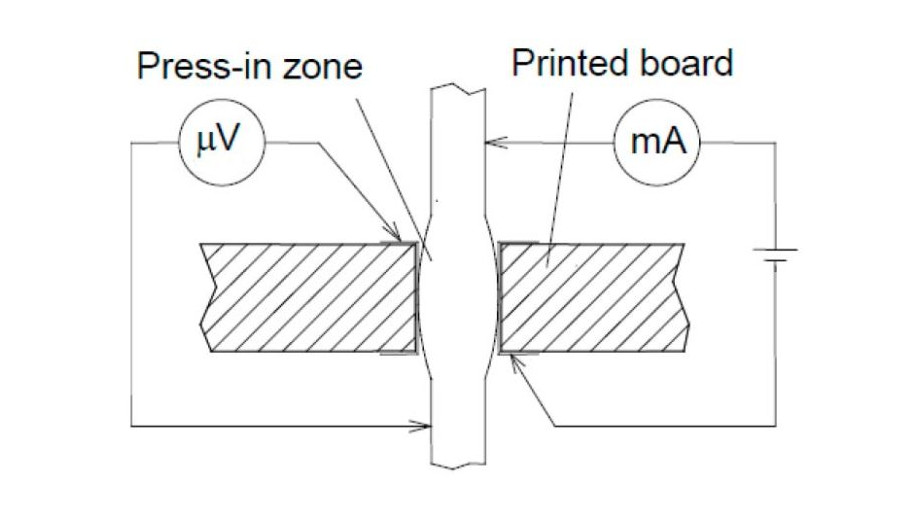

qualified in accordance with IEC 60352-5, Press-in connections (report available on request);

It proved to have required contact resistance (< 0.5 mΩ), no cracks, acceptable deformations and resistance to rapid temperature changes and climate sequences.

- small size of the pin affects the price downwards;

0.4x0.5 mm Press-fit pin’s reduced cost is based on its manufacturing process. It is a drawn-wire product with no-waste of raw material, and offers a high level of customization without non-returnable investment of any kind.

-

suitable for Nano MQS connector family;

- small pin size and distance between inserted pins allows for use in compact spaces, which is very important in the automotive industry.

[gallery link="file" ids="6832,4272,6774"]

Characteristics and requirements:

- press-in force - less than 60 N, average 42 N;

- push-out force - more than 50 N, average 73 N;

- recommended PCB hole for insertion - Ø 0.6 mm;

- hole pitch 1.6 mm (compare with standard 0.6 mm pin pitch in 2/2.5 mm) - can be wider on request;

- pin material CuNiSi - K55, hardened copper alloy with excellent spring properties and good corrosion resistance. It combines medium electrical conductivity with high strength and good relaxation behaviour.

End-to-end supply

End-to-end supply

Pins are supplied in plastic reels in end-to-end format. Reels are compact (Ø 800 mm), easy to change and rechargeable. Each contains approximately 200 000 pins. End-to-end format means you don't have to waste extra material.

[gallery link="file" columns="2" size="large" ids="6902,6906"]

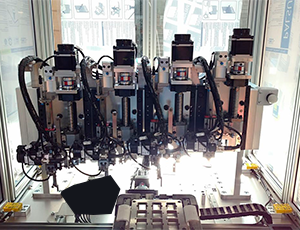

Pin insertion equipment

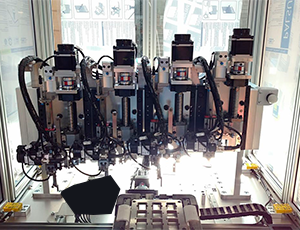

Assembly of 0.4x0.5 mm press-fit terminals to PCB can be efficiently accomplished with SM Contact insertion equipment and a custom-designed insertion head. Pininsert machines can feed, cut and insert a single pin in full automatic mode, with a tack time around up to 0.3 sec per pin.

| Pininsert 2100 and Pininsert 2100 XL |

Pininsert 3200 |

| Semi-automatic pin insertion into the PCB. Stand-alone or inline machine for small and medium production volumes (up to 3 600 pins per hour). |

Conveyor version of high-volume semi-automatic pin insertion into PCB. |

|

|

Pin bending

Pin bending

0.4x0.5 mm press-fit pins offer various ways to process shape modifications as necessary. It’s possible to perform electrical connections at 90 degrees in order to optimise spaces. Bending module can be:

-

stand-alone or integrated into the machine,

- with conveyor or manual loading of PCB.

Bending of pins can be performed either before or after insertion into PCB:

| Bending before insertion |

Bending after insertion |

|

|

In addition to 0.4x0.5 mm, the following press-fit pins have been in production at SM Contact for over a decade:

0.6 x 1 mm,

0.63 x 0.63 mm,

0.6 x 1.2 mm,

0.8 x 1.4 mm.

Please send requests to SM Contact team smcontact@smcontact.eu Advantages of 0.4x0.5 mm press-fit pins:

- qualified in accordance with IEC 60352-5, Press-in connections (report available on request);

It proved to have required contact resistance (< 0.5 mΩ), no cracks, acceptable deformations and resistance to rapid temperature changes and climate sequences.

- small size of the pin affects the price downwards;

0.4x0.5 mm Press-fit pin’s reduced cost is based on its manufacturing process. It is a drawn-wire product with no-waste of raw material, and offers a high level of customization without non-returnable investment of any kind.

- suitable for Nano MQS connector family;

- small pin size and distance between inserted pins allows for use in compact spaces, which is very important in the automotive industry.

[gallery link="file" ids="6832,4272,6774"]

Characteristics and requirements:

- press-in force - less than 60 N, average 42 N;

- push-out force - more than 50 N, average 73 N;

- recommended PCB hole for insertion - Ø 0.6 mm;

- hole pitch 1.6 mm (compare with standard 0.6 mm pin pitch in 2/2.5 mm) - can be wider on request;

- pin material CuNiSi - K55, hardened copper alloy with excellent spring properties and good corrosion resistance. It combines medium electrical conductivity with high strength and good relaxation behaviour.

Advantages of 0.4x0.5 mm press-fit pins:

- qualified in accordance with IEC 60352-5, Press-in connections (report available on request);

It proved to have required contact resistance (< 0.5 mΩ), no cracks, acceptable deformations and resistance to rapid temperature changes and climate sequences.

- small size of the pin affects the price downwards;

0.4x0.5 mm Press-fit pin’s reduced cost is based on its manufacturing process. It is a drawn-wire product with no-waste of raw material, and offers a high level of customization without non-returnable investment of any kind.

- suitable for Nano MQS connector family;

- small pin size and distance between inserted pins allows for use in compact spaces, which is very important in the automotive industry.

[gallery link="file" ids="6832,4272,6774"]

Characteristics and requirements:

- press-in force - less than 60 N, average 42 N;

- push-out force - more than 50 N, average 73 N;

- recommended PCB hole for insertion - Ø 0.6 mm;

- hole pitch 1.6 mm (compare with standard 0.6 mm pin pitch in 2/2.5 mm) - can be wider on request;

- pin material CuNiSi - K55, hardened copper alloy with excellent spring properties and good corrosion resistance. It combines medium electrical conductivity with high strength and good relaxation behaviour.

End-to-end supply

Pins are supplied in plastic reels in end-to-end format. Reels are compact (Ø 800 mm), easy to change and rechargeable. Each contains approximately 200 000 pins. End-to-end format means you don't have to waste extra material.

[gallery link="file" columns="2" size="large" ids="6902,6906"]

Pin insertion equipment

Assembly of 0.4x0.5 mm press-fit terminals to PCB can be efficiently accomplished with SM Contact insertion equipment and a custom-designed insertion head. Pininsert machines can feed, cut and insert a single pin in full automatic mode, with a tack time around up to 0.3 sec per pin.

End-to-end supply

Pins are supplied in plastic reels in end-to-end format. Reels are compact (Ø 800 mm), easy to change and rechargeable. Each contains approximately 200 000 pins. End-to-end format means you don't have to waste extra material.

[gallery link="file" columns="2" size="large" ids="6902,6906"]

Pin insertion equipment

Assembly of 0.4x0.5 mm press-fit terminals to PCB can be efficiently accomplished with SM Contact insertion equipment and a custom-designed insertion head. Pininsert machines can feed, cut and insert a single pin in full automatic mode, with a tack time around up to 0.3 sec per pin.

Pin bending

0.4x0.5 mm press-fit pins offer various ways to process shape modifications as necessary. It’s possible to perform electrical connections at 90 degrees in order to optimise spaces. Bending module can be:

- stand-alone or integrated into the machine,

- with conveyor or manual loading of PCB.

Pin bending

0.4x0.5 mm press-fit pins offer various ways to process shape modifications as necessary. It’s possible to perform electrical connections at 90 degrees in order to optimise spaces. Bending module can be:

- stand-alone or integrated into the machine,

- with conveyor or manual loading of PCB.

Bending of pins can be performed either before or after insertion into PCB:

Bending of pins can be performed either before or after insertion into PCB:

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957