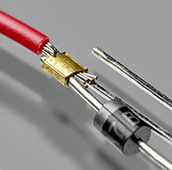

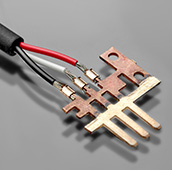

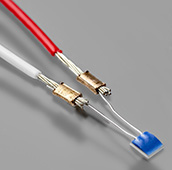

SPLICE CRIMPING

SM Crimp V8 operation includes components manual positioning, when operator holds components within the splice area, and splice crimping by pressing the pedal.

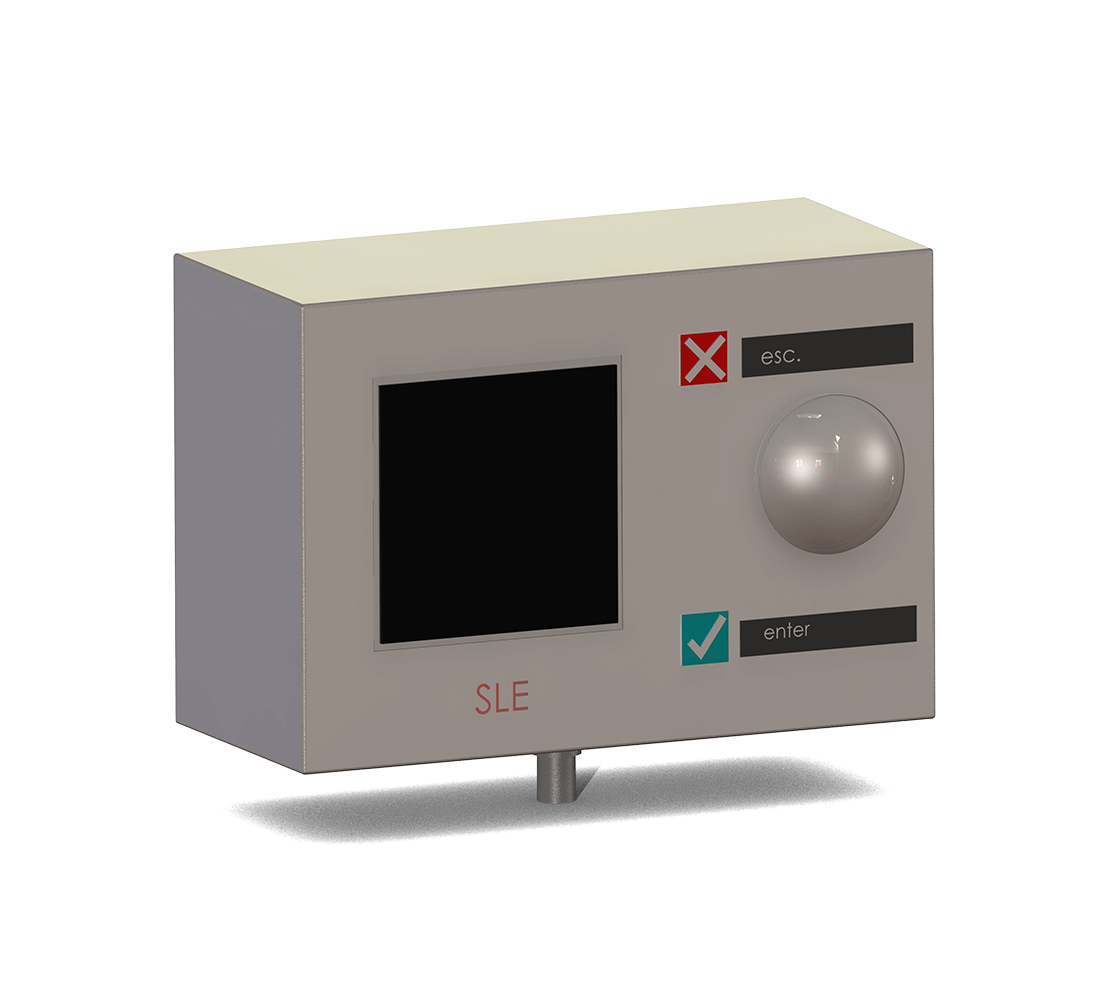

Touch screen control panel (instead of manual buttons in the earlier models):

– displays information about tooling and connection,

– lets choose connection with preadjusted heights,

– detects position of main shaft by encoder,

– transmits picture from camera in the cassette and data from the built-in CFM.

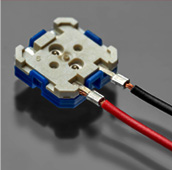

Tool cassette can be designed for a wide range of wire cross-sections, e.g. 0.5-1.5 mm2. What is more, changing only the cassette it is possible to perform various connections with the same splice band.

SPECIFICATIONS:

– automatic crimp height adjustment with position controlled by encoder

– built-in CFM

– built-in component position video verification

– easy punch return to zero position

– plug-and-play fixture installation

– сan be integrated into automatic production line

RELATED TOPICS

+86- 20-3992 0957

+86- 20-3992 0957

info@smcontact.cn

www.smcontact.cn