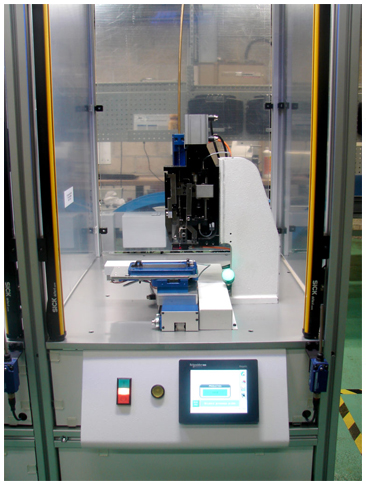

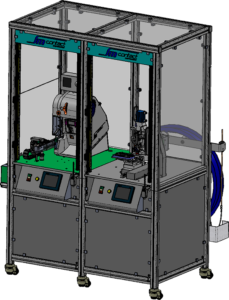

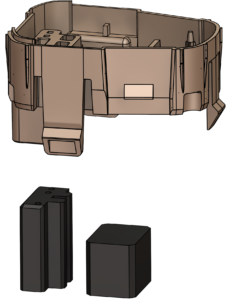

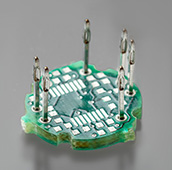

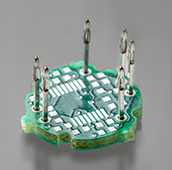

Pininsert 2100 is a pneumatic or servo-drive table-mount machine for semi-automatic pin insertion into various electrical components. It was designed as stand-alone or inline machine for small and medium production volumes (up to 3 600 pins per hour).

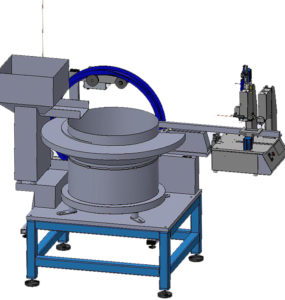

Components are located on the manually-adjustable working table. Operator moves it to the work zone where pins are inserted one at a time in automatic (option), step-by-step and manual operation modes. Table can be motorized on demand.

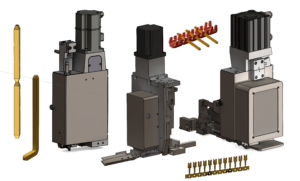

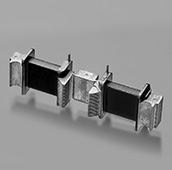

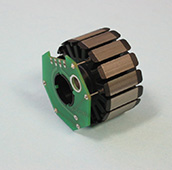

Interchangeable insertion head makes it possible to produce various applications on one machine.

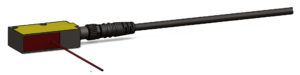

Camera and laser control assures correct positioning of the components and pin.

English

English

Chinese

Chinese

+86- 20-3992 0957

+86- 20-3992 0957